Our Valuable Clients

ABOUT Meight – Company Profile

Welcome to Meight Engitech Private Limited

Welcome to Meight Engitech Private Limited, where engineering excellence meets technological innovation. An engineering company providing custom engineering with updated technology and specialised research on metallurgy

MEIGHT ENGITECH PRIVATE LIMITED established in 2021 with motto of Engineering with Technology

Meight engitech Pvt. Ltd. is a high quality equipment fabricator for exotic materials such as Titanium, Tantalum, Nickel, Alloy 904L, HasteLoy B & C, Monel, Inconel, Alloy 20, Zirconium, Duplex Steel 2205 & Super Duplex 2507. Good qualified engineers and experienced technocrats never compromise for quality in tailoring the products. This has been maintained positively for all our product ranges.

We manufacturer of different type of Storage Tank, Coil from different alloys, Heat exchanger , Mixing Tank, Chemical Reactor, Air Receiver Tank, Structure Fabrication, Piping System, SS Fabrication, Industrial Chimney etc.

At Meight , we take pride in building long-term, personal family relationships with our clients, driven by our commitment to delivering comprehensive, high-quality solutions. Our design, engineering, and manufacturing processes are tailored to meet individual specifications while adhering to recognized industry codes and standards. The dedication to work, immediate response to all kinds of customers and through timely delivery of the products.

OUR PRODUCTS

Explore Our Products

OUR SPECIALIZATION

Perfect Solutions For Any Industrials

We have also following Essential Testing Facilities

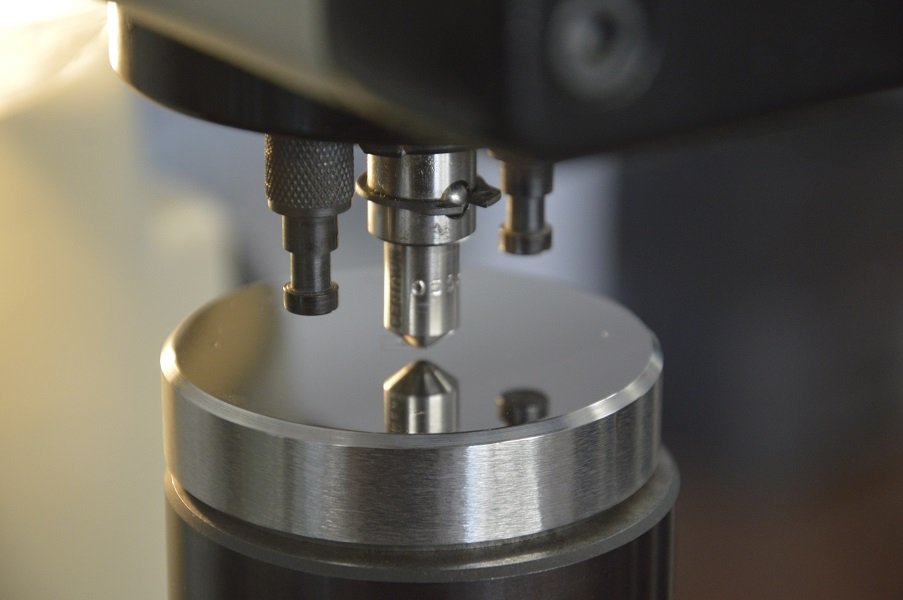

Mechanical Testing

Tensile testing, impact testing, hardness testing, and fatigue testing to assess material strength and performance.

Non-Destructive Testing (NDT)

Methods like ultrasonic testing, radiography, and magnetic particle testing are used to detect internal flaws without damaging the product.

Material Analysis

Spectroscopy and other analytical techniques can be used to determine the chemical composition and other properties of materials.

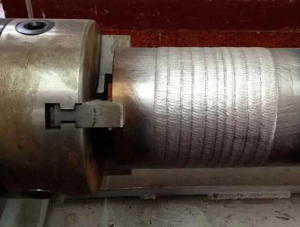

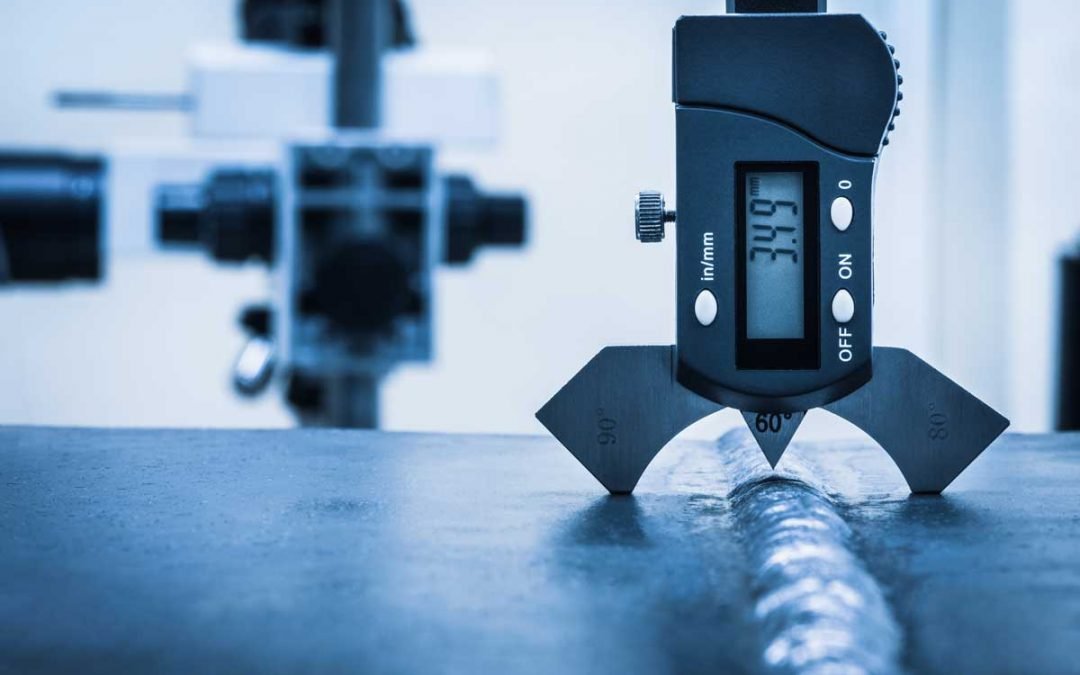

Dimensional Measurement

Micrometers, callipers, height gauges, and coordinate measuring machines (CMMs) are used to verify dimensions and tolerances.

Weld Testing

This includes visual inspection, NDT, and mechanical testing of weld joints to ensure their strength and integrity.

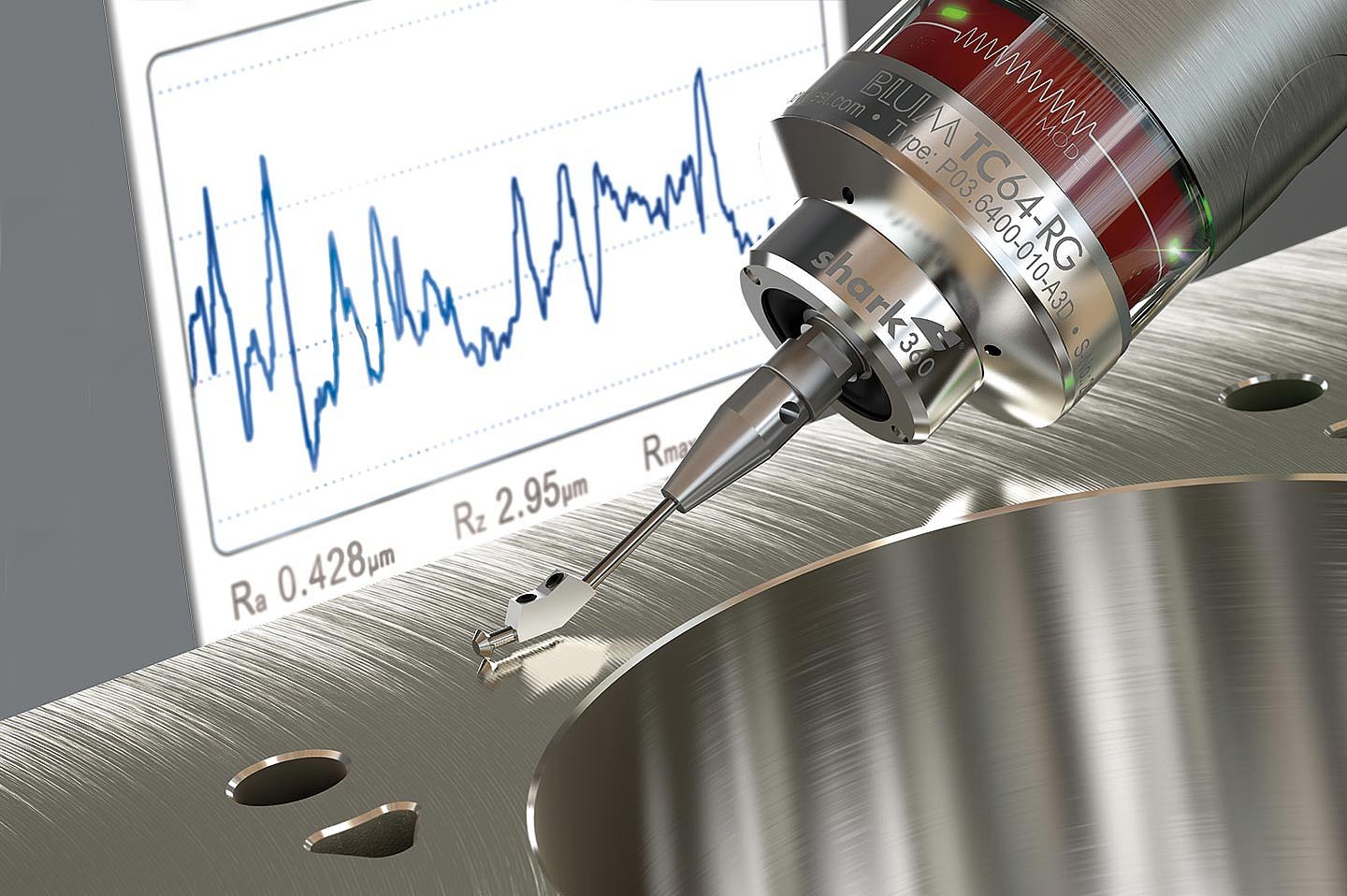

Surface Finish Testing

This can involve testing for surface roughness, coating thickness, and other aspects of surface finish.

Perfect Solutions For Any Industrials

TESTIMONIALS

What Our Clients Say

OUR BLOG